40+ years of combining the values of a small, personalized, familial organization with the manufacturing scope & scale of a large company.

All American Poly is a leader in innovation and sustainability

keeping our customers of the forefront of leading-edge

technology, processes and products that provide you

competitive advantage and help grow your

market share and earnings.

At AAP we’re all about the

Poly

Specializing in low-density and linear low-density polyethylene products, we provide you with high performance innovative polyethylene packaging solutions by

People

developing vibrant partnerships that combine family values, exemplary service, and the flexibility to turbocharge your business toward success

Unrivaled supplier for the following industries

Agriculture

Bedding

Beverage

Building Supplies

Corrugated

Chemical

Foam

Food

Furniture

Glass

Paper

Textile

Our Product Development Process

How it worksWe’re the largest, privately-held polyethylene extruder in the U.S.

3

Manufacturing plants

450+

Employees

18+

18+ 3PL

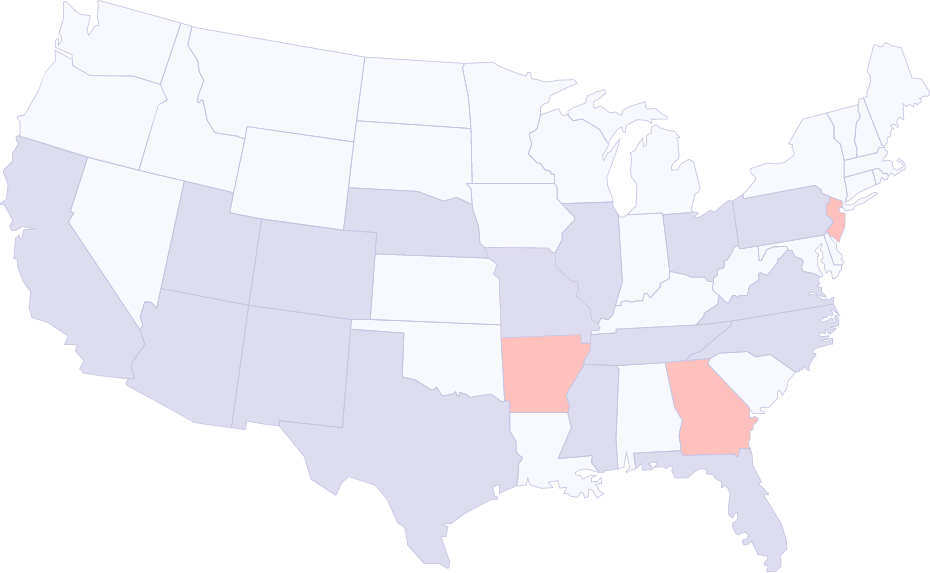

Where we are.

Manufacturing Plants

Little Rock

309 Phillips Road, N. Little Rock, AR 72117 (800) 526 3551

3 PL's

Manufacturing Plant