PERFORMANCE PRODUCTS

Your business is unique.

We’ll create a product that is a seamless fit.

Cost Efficient

Yield gains upward of 30% per roll – each roll unwinds and functions right to the core

Faster Wrapping

Increased machine throughput of up to 35%

Flawless Performance

Precisely calibrated rolls for steady machinery feed, 100% performance guaranteed

Independence®

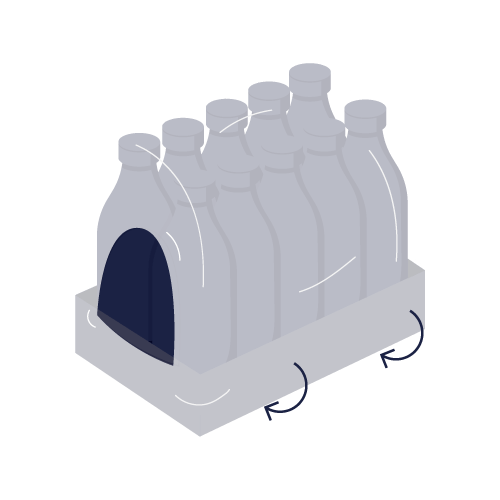

Shrink Bundling

Free to run, unsupported.

Cost Efficient

Use less film per unit. Our films provide yield gains upwards of 30%.

Energy Saving

Reduce your energy consumption and temperatures downwards of 40°.

Flawless Performance

Consistent product integrity has reduced our claims to 0%.

Faster Wrapping

Gain productivity with increased throughput of up to 35%.

Independence™ is one of our greatest innovations. Unrestricted by equipment types, this film is proven to run full speed ahead, commonly at lower temperatures, resulting in impressively formed packages with a high level of integrity. Engineered to honor critical performance values, for success in downgauging and liberating packages from corrugated support.

Wrap bulk-packs and cases for stacking, shipping and shelving while protecting contents from breakage, theft, and tampering” after first paragraph and before the block that begins with “tray removal to pad.

- Tray removal to pad

- Unsupported packs

- Gauge optimization

Valiant®

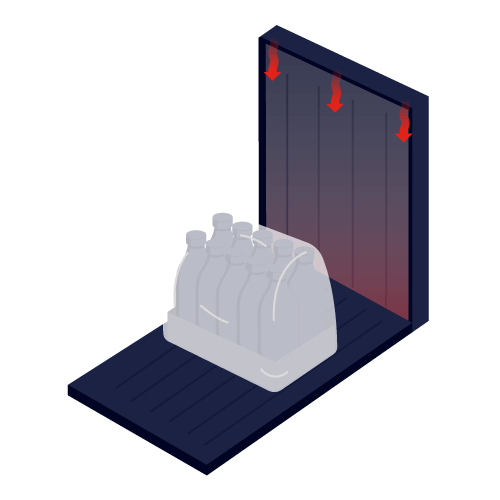

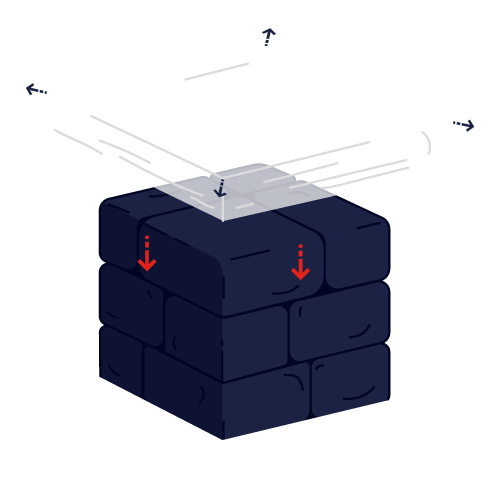

Shrink Hooder

Shrink hooders use heat to shrink wrap your pallet, providing airtight protection and stability for shipping and storage. Protective properties make shrink hooder ideal for transporting fragile merchandise such as glass, insulation, tiles, textiles and paper.

Airtight – Our shrink hooder is constructed for a secure, water-resistant sealed cover, locking out dust, moisture and other damaging elements. This makes ValiantTM the preferred method for wrapping sensitive products such as glass, tiles, insulation, textiles and paper.

Adaptable – Engineered with bold shrink force, ValiantTM is manufactured by equipment intended for the ultimate balance of horizontal and vertical shrink. In conjunction, this product is responsive to an array of hooding machines and processes for a complete and well-contained fit.

Valiant™ is available in a wide range of widths for various pallet sizes and footprints, and with ODs of up to 40

Sturdy – ValiantTM is courageously formulated with stiffness that does not compromise sealability, for a pallet that is highly-secured and ready for the rigors of shipping and handling.

Reputable – ValiantTM is the plastic of choice in the building supplies industry for products such as glass, insulation, tiles, textiles and paper.

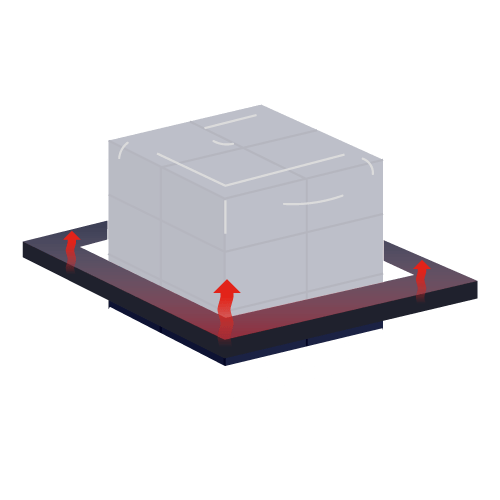

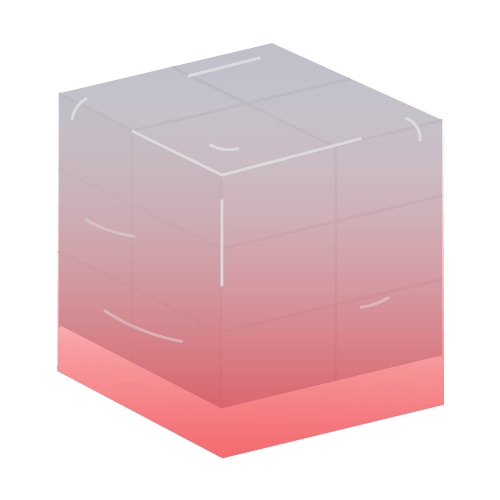

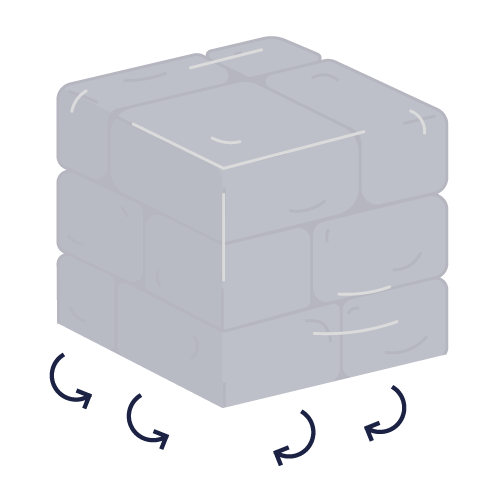

Unite®

Stretch Hooder

All American Poly’s Unite™ has been coined by one of the major OEMs as “the best stretch hooder in North America.

Unwavering Performance – We’ve taken special care with our co-extruded film; each layer of UniteTM has been engineered with a specific and consistent function for utmost performance.

Balanced Tension – UniteTM rolls are precisely calibrated for steady machinery feed, 100% performance guaranteed. Features include flawless load application, stress resistance, and extraordinary strength.

Unite™ is available in a wide range of widths for various pallet and load footprint.

Elastic – UniteTM stretches to maximum parameters and

holds its integrity throughout the pre-stretching and packaging process

Weatherable – Endures exposure to any of the elements over prolonged time. Validated across the nation in extreme and varying climates.

The film that runs on autopilot:” An energy efficient wrapping solution that fits seamlessly over pallets.

Maximize Output – Each roll of UniteTM unwinds with ease and functions fully to the core, maximizing units wrapped, avoiding re-wraps, machine down time, and extra labor. Elect for 40” ODs and reduce change over time.

Minimize Waste – Unite’s components and manufacturing process accomplishes a sustainable stretch hooder product, reducing our carbon footprint and promoting productivity, all while minimizing costs.

Customization Capabilities

Every production line is different. That’s why we formulate our performance products to precisely meet your needs.